Quality

WE DON’T LET ERRORS HAVE A CHANCE

If you want to reduce quality-related costs and increase customer satisfaction, you must have maximum transparency about the error landscape and identify its causes. We ensure the design and continuous improvement of reactive and preventive quality work at the organizational, process and product levels.

Optimization of the quality organization

Quality has many contributors and, especially with increasing product digitalization, networking and intersections are becoming more and more common. Therefore, we analyze the quality organization across the entire product creation process from development to purchasing and production to after sales.

To evaluate the performance of your quality management against benchmarks from mobility industries, we often apply our proven Q-Scan and derive a set of measures as well as organizational alternatives. On this basis, we work with you to create your new operating model, including defined processes, methods, roles, and tools.

It is important to us to achieve the highest possible quality not only reactively, but also preventively, i.e., already in product development and production, in order to sustainably increase the efficiency of your company and reduce the sum of all quality costs.

Sustainable defect management

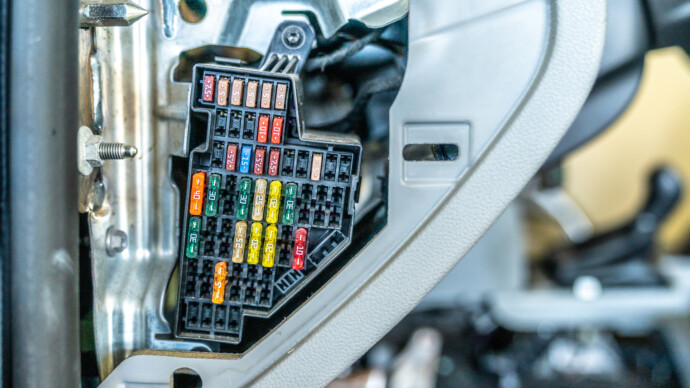

The increased requirements due to the networking of digital products in particular require faster and more efficient defect management in their (further) development. An important factor is the early detection of errors, whereby we provide our customers with a great deal of assistance in the definition of safeguarding strategies and cascades.

The reduction of errors in development and in the field must then be accelerated via a high level of transparency and standardization of the control and escalation processes. We help our customers to set up lean processes that are adapted to the product and company structure.

Since there is a process problem behind every product problem, we have also developed simple methods for root cause analysis that identify process weaknesses along the entire value chain. In this way, repeat defects of future product generations can be avoided and quick-win measures for short-term improvements can still be taken for products in development.

Reduction of the Total Cost of Quality

Quality-related costs are a non-negligible item in the operational P&L. The problem often lies in the intangible assets of the company. The problem often lies in the lack of transparency of these cost blocks and thus a weakness in the argumentation for their optimization.

Thanks to our expertise from numerous quality projects, we have developed a simple system with which we can record the sum of all quality-related costs over the entire product life cycle and then identify the right levers.

This is not just about reducing your non-conformance costs (error costs that occur at the customer, e.g., costs that are incurred by the customer).e.g. warranty costs), but also to consider compliance costs (all costs for preventive quality measures, e.g. testing and safeguarding) in order to achieve an optimum of efficiency and effectiveness.

Identification and avoidance of recall actions

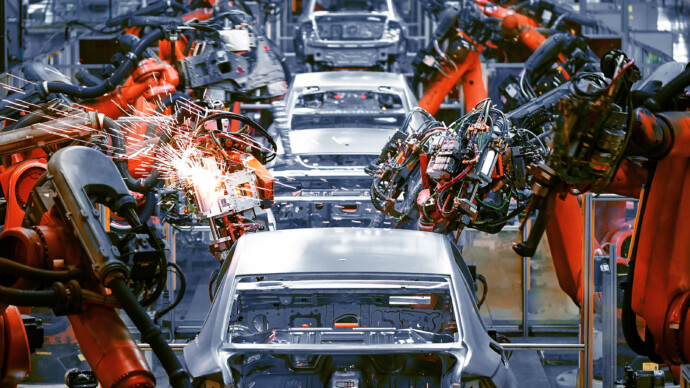

Much-used modular systems affecting very high product populations, more and more customer functions, unstable supply chains: The risks of recalls and recall volumes have continuously increased in recent years. To counter this risk, we support you in three key areas:

To prevent recalls, we build on root cause retrace to prevent defects for next product generations, ensure transparency on quality performance in the supply chain and early detection of recalls based on criticality of field anomalies.

To reduce the impact of recalls, we help with measures to optimize repair processes, reduce volumes, and ensure compliance with regulatory requirements.

When managing recalls, we help you to consistently track measures, build demand and population control, and establish detailed planning of total costs.