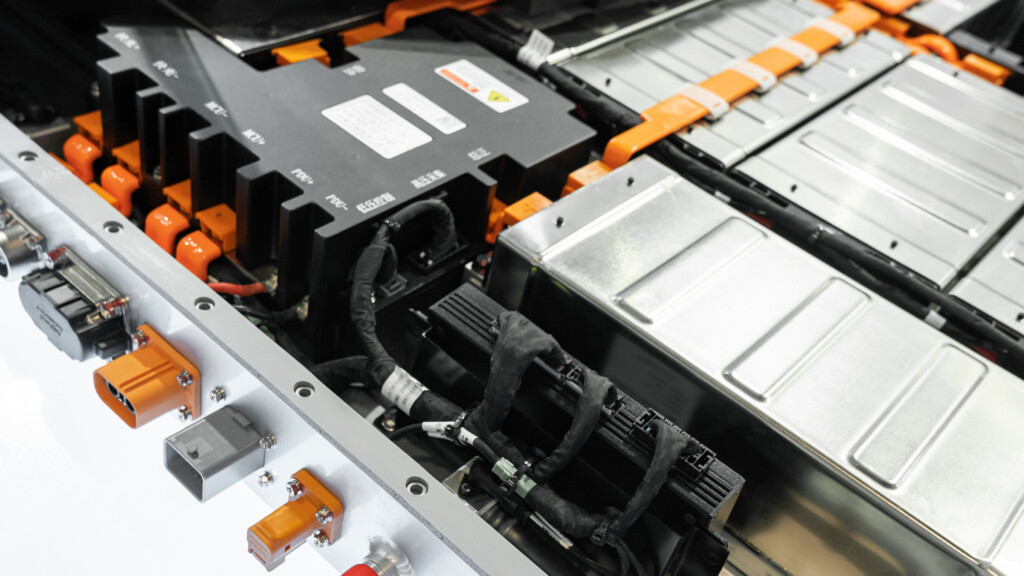

Project Example

Ensuring Timely Plant Ramp-up of a Module Production for Battery Electric Vehicles

An automobile manufacturer faced the challenge of implementing module production for battery electric vehicles on schedule. The ramp-up of the plants was significantly impacted by the global pandemic and the associated restrictions on travel and personnel availability. Despite these adverse circumstances, it was necessary to create transparency and commitment in project progress.

Background

Significant delays in relevant trades occurred early in the project phase, encompassing over 50 individual plants within the production facility. The project’s complexity was high due to the involvement of numerous trades from different countries. Against this backdrop, clear communication and decision-making ability were necessary to ensure the timely ramp-up of the plants.

Specific Task

Our goal was to create transparency about the status of plants and components to facilitate the re-prioritization of content and consistent tracking of schedules. This also included conducting supplier visits and escalating issues that jeopardized the Start-of-Production (SOP) process of the time-critical production facility.

KBC Solution Approach

We ensured constant transparency regarding progress and action needs. We guaranteed communication up to the board level through management-capable reporting. This approach laid the foundation for a timely ramp-up of module production despite the challenges of the global pandemic.